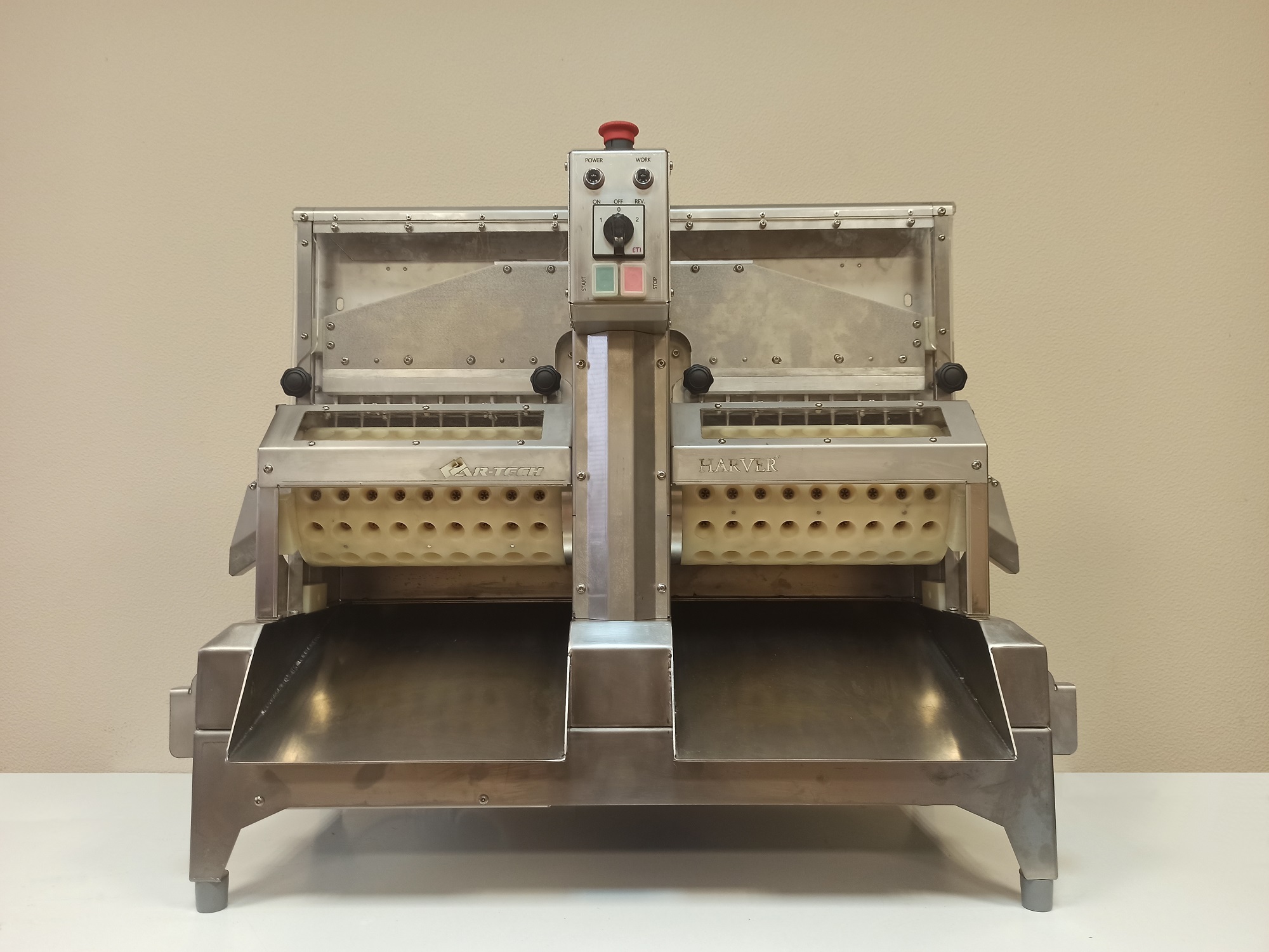

The AR - Tech company presents to your attention our new development - the Harver DM300x2 Cherry pitting machine. The machine is designed for dividing out pits from fresh cherries and sweet cherries. The capacity of this machine depends on the size of the fruit and averages 250 - 300 kg/hour.

The machine is almost entirely made of food grade stainless steel AISI304, as well as caprolon and duralumin. Its structure complies with all applicable safety, sanitary and hygienic standards and is suitable for use in enterprises and workshops of the food industry.

Features:

- The machine works with both small cherries and large cherries and sweet cherries.

- Fruit diameter - from 18 to 28 mm.

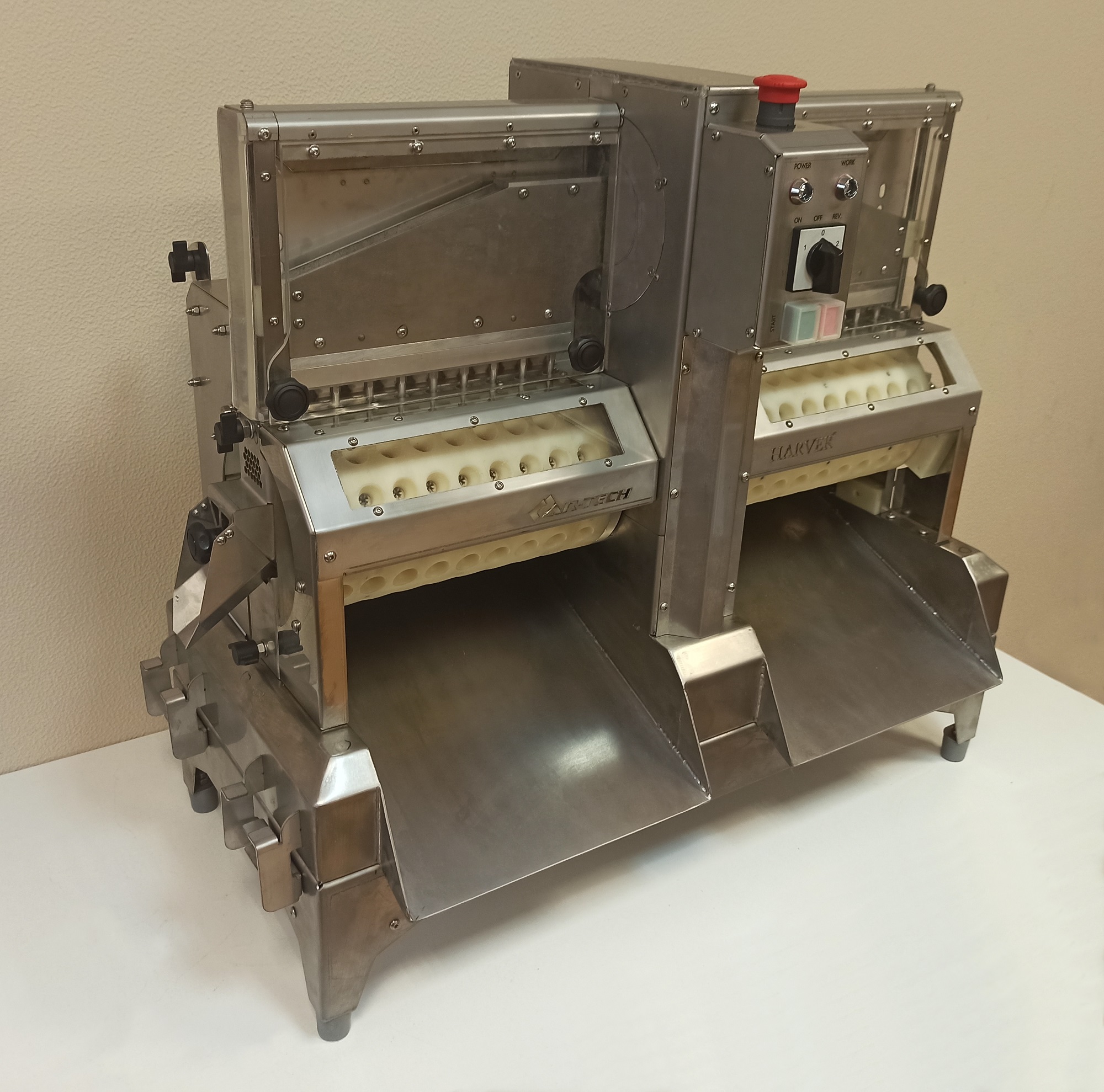

- High capacity: 1260 pitted cherries per minute, 18 cherries at the same time.

- Substantial savings in time and operating costs.

- The feeding of new fruits into the cells is automatic.

- Easy to clean and maintain.

- The corresponding parts of the machine can be easily removed and washed.

- The shortest payback period due to high capacity and low cost compared to other similar machines.

- 12 months warranty.

HARVER DM300x2 is an industrial type machine for use in confectionery and bakery shops, as well as small businesses for freezing fruits or the production of dried fruits. The machine is not a home appliance and requires qualified service personnel.

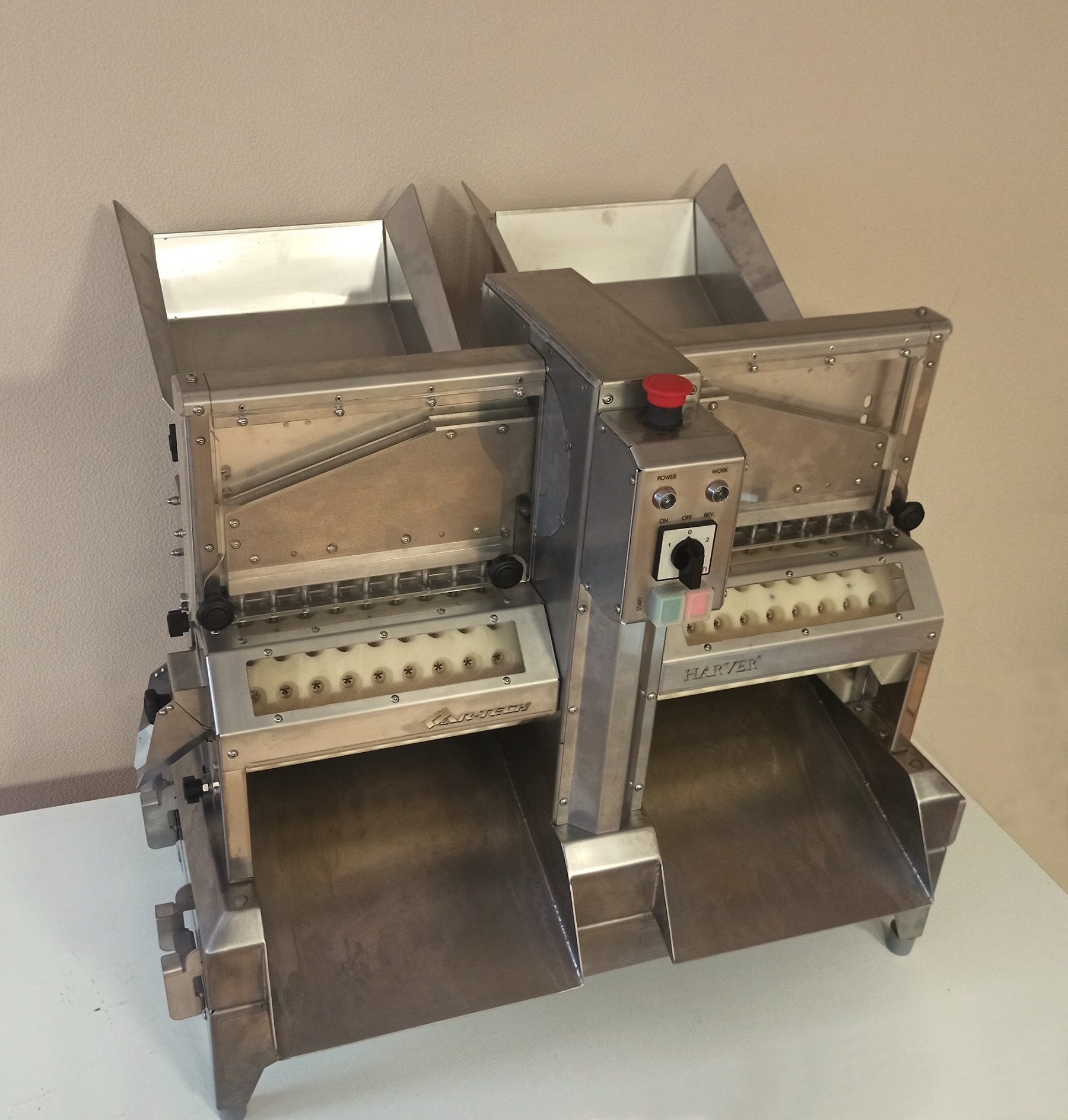

Principle of operation:

The cherries are loaded into a receiving container and rolled into cells in the working drums, which rotate 12 steps per full turnover. The cherries that have fallen into the appropriate cells are delivered to the processing area, where sharp, specially shaped plungers, penetrating the center of the fruit, remove the stone, directing it into the hole with a rubber cuff. The pits fall into the pits reciever with the screw, which takes them out of the working area. The plungers return to their original position, the drum rotates for the next steps and the beaten out cherries fall out on the other side of the machine, falling into the collection container installed by the operator.